Reducing The Size Of Coarse Line Using Crushing Plant

Optimization Capabilities for Crushing Plants Chalmers

a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure 2017年3月4日 — The details of size reduction methods involved in mineral processing are using crushing equipments (Balasubramanian, 2017) Ore dressing is a process of mechanically separating the(PDF) SIZE REDUCTION BY CRUSHING A comminution process is defined as the size reduction of particles, while a classification process is defined as the separation of particles based on size, shape, and material Optimization Framework for Crushing Plants Chalmers2024年9月18日 — • Reduce the material to a size that can be processed by the following equipment The purpose of the primary stage is not very much involved in the actual CRUSHING PLANT PROCESS OPTIMISATION AusIMM

Advanced comminution modelling: Part 1 – Crushers☆

2020年12月1日 — To get from the ROM (runofmine) size to the required product size usually requires several incremental steps that progressively reduce the particle size 2022年4月26日 — The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective in minerals(PDF) Optimization Capabilities for Crushing 2020年6月4日 — The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing Evaluation of size reduction process for rock aggregates in 2020年2月8日 — This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal Aggregate Production Optimization in a StoneCrushing Plant Using

.jpg)

Understanding Mineral Liberation during

2020年2月13日 — Understanding how compressional breakage influences mineral liberation is an important first step to identify ores that have suitable characteristics for preconcentration There are multiple models that 2024年9月24日 — There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production Crushing Plant Design and Layout Considerations 911 2017年3月4日 — The details of size reduction methods involved in mineral processing are using crushing equipments (Balasubramanian, 2017) Ore dressing is a process of mechanically separating the grains of (PDF) SIZE REDUCTION BY CRUSHING a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the aggregates industry is to development for coarse comminution process A case study of Geita gold mine, Tanzania using Plantsmith process simulatorOptimization Capabilities for Crushing Plants Chalmers

.jpg)

How it Works: Crushers, Grinding Mills and

2017年6月2日 — Rittinger’s Law states that the energy required in size reduction is proportional to the new surface created by the particle fragmentation The equation for Rittinger’s Law can be written as: E = K 2024年9月24日 — %PDF12 %âãÏÓ 114 0 obj /Linearized 1 /O 116 /H [ 1107 524 ] /L /E 29615 /N 29 /T >> endobj xref 114 34 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 911 Metallurgist2023年12月1日 — 2 All crushers have a limited reduction ratio meaning that size reduction will take place in stages 32 Operation stages: The operating stages in minerals processing have remained the same for SIZE REDUCTION BY CRUSHING METHODS ByCrushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple , the ore is blended and fed to crusher by loader bucket for size reduction Crushing is (PDF) Field monitoring and performance evaluation of crushing plant

WHAT IS THE CRUSHING PROCESS? MEKA

Crushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing" Although there is no limit set, the downsizing process over 3 mm is considered as "crushing 2024年9月18日 — purpose of size reduction and often also classifi cation The confi guration of a crushing stage varies Using dynamic simulation of crushing plants will also need a lot more information then what normally is available at the design phase of the crushing plant construction A steady state simulation of a crushing plant begins with the CRUSHING PLANT PROCESS OPTIMISATION AusIMMA research group now known as the Julius Kruttschnitt Mineral Research Centre at the University of Queensland has been working since 1962 on the simulation, optimization and control of mineral treatment processes The initial work was on the grinding and classification processes This work has been very successful in the optimization (Lynch, [PDF] The Simulation of Crushing Plants with Models Developed using 2023年2月28日 — The primary objective of crushing is to reduce the size of the materials for further processing Crushing is an energyintensive process that involves different types of equipment, such as crushers, screens, and conveyors 200t/h Pebble Crushing Mobile Production Line; 150t/h Granite Mobile Crushing Plant; 100t/h Slag Mobile Crushing Plant Primary and Secondary Crushing: Understanding the Basics

.jpg)

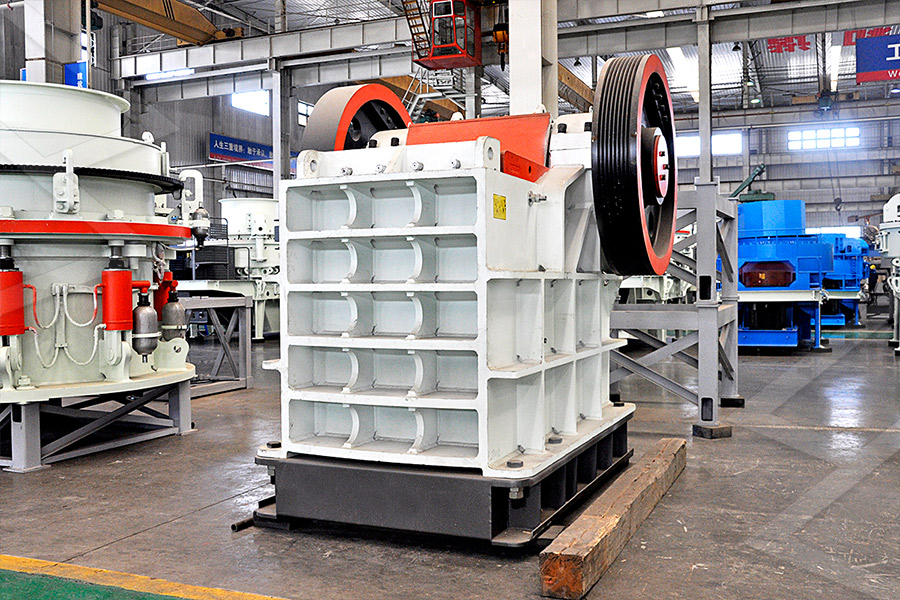

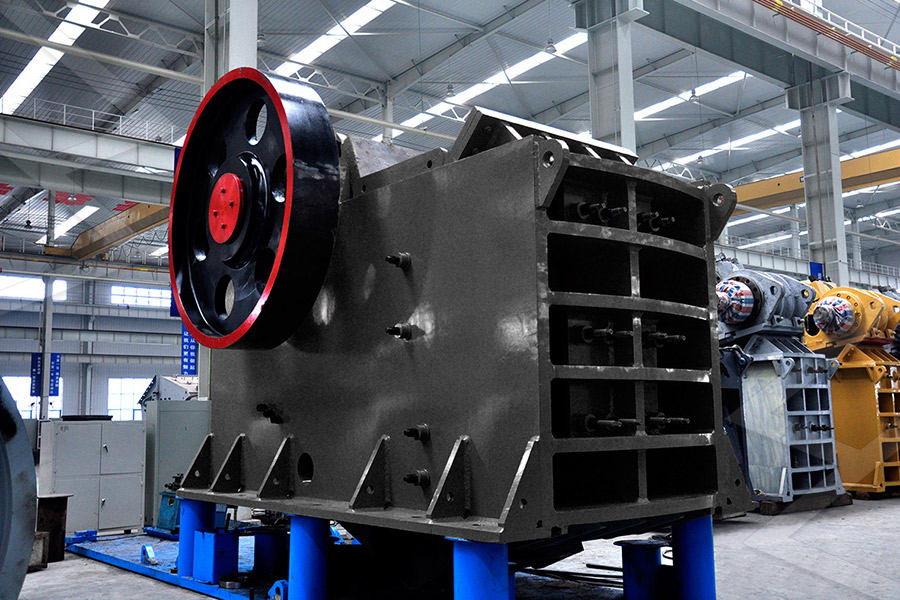

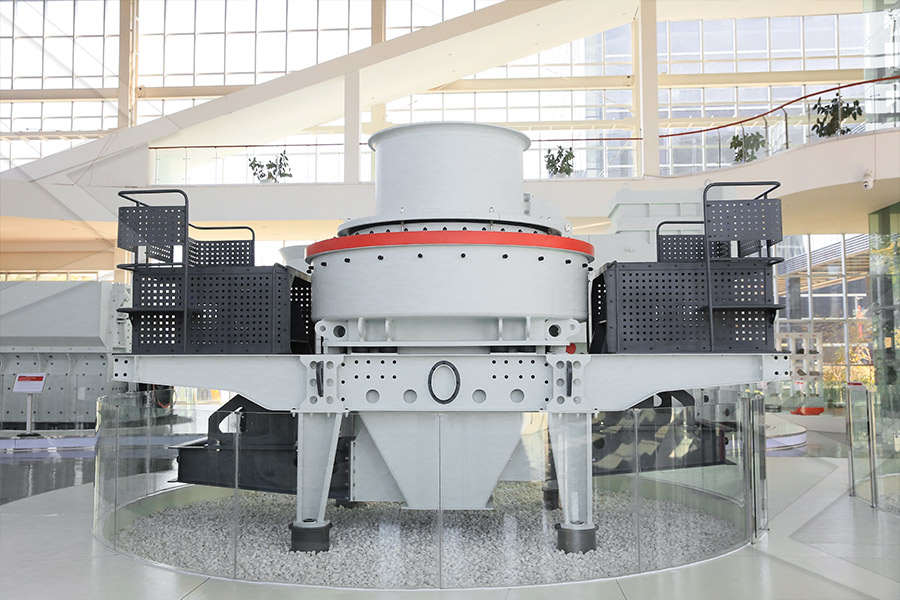

Types of Crushers Explained: Everything You

2024年4月19日 — The crushing process is commonly conducted in several stages Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material The first step is 2020年6月4日 — The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several Evaluation of size reduction process for rock aggregates in 2016年4月14日 — Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced Crushing Screening Plant Design Factors2024年7月17日 — Two main ways of crushing Crushers reduce the size of materials by applying mechanical force In the mining and construction industries, the most commonly used crushing methods are compression crushing and impact crushing and small crushing production lines They are currently one of the bestselling crushers on the Types of Crushers: Choosing the Right One for Each Stage

.jpg)

Crushing Plant Design and Layout Considerations 911

2024年9月24日 — crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climatic2021年7月6日 — Crushing and grinding are known as comminution procedure where the major operations are intensively related to liberation and reduction of particle size by means of different technologies(PDF) Comminution a Heart of Mineral Processing2020年4月20日 — Crushing is the process of reducing the size of materials so that they can be further processed In addition to being used in the chemical, coal industry, constrction area and so on area, industrial crushing equipment can be very useful in those variety of businesses a processing line at a mine may crush rock ore into smaller pieces before Crushing in Mineral Processing Eastman Rock CrusherNonmetallic mineral material will be first quarried and then conveyed to the processing plant for further classification or further size reduction by the aggregate crushing plant A crushing plant is a onestop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing, and other similar Demystifying the Crusher Plant: A Comprehensive Guide to

.jpg)

Ore Crushing SpringerLink

2023年7月22日 — The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm The maximum crushing ratio of coarse crushing is about three The main force in the 2020年1月1日 — Some of the size reduction operations are crushing, milling, grinding, dicing, etc (SudSushant et al, 2013;Mulla et al, 2016; Kumar and Yedhu Krishnan, 2020) The size reduction creates a new (PDF) A Review on the Technology of Size Reduction Equipment 2021年6月24日 — 700mm coarse SD 285 t/m3 Abr 1227 g/t Cr 20 % 450 B13503V Load 75 % 450 Opening 100 mm 305 145 Lokotrack primary mobile crushing plant to further processing stages They are able to follow parameters online Original wear and spare parts – using original Metso wear parts is the key to a successfulCrushing and Screening Handbook AusIMM2024年1月11日 — The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw Limestone Crushing And SandMaking Plant

.jpg)

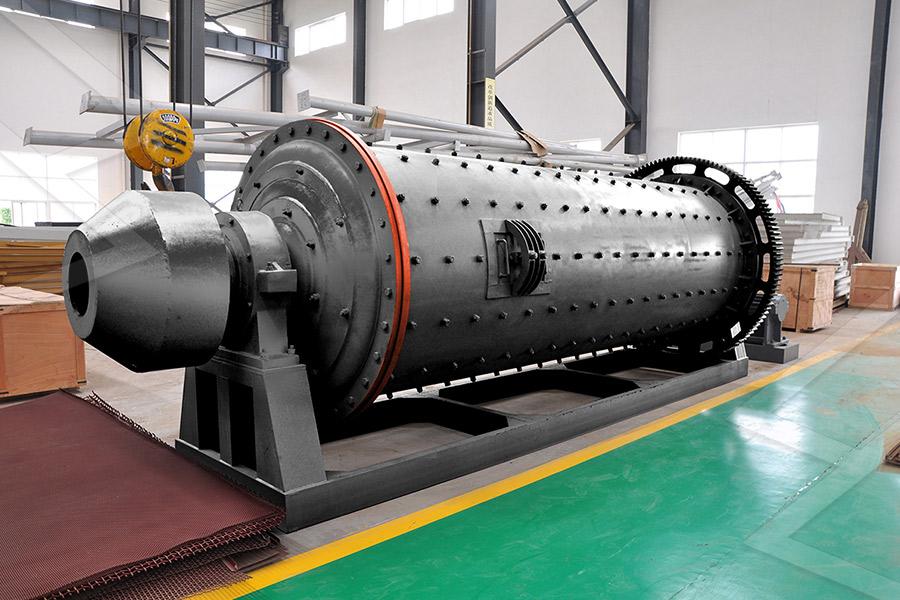

Size Reduction – Visual Encyclopedia of

5 天之前 — Pin mills are used to reduce the size of medium to lowdensity materials such as talc and clay Pin mills use centrifugal forces to smash large particles against pins Equipment Design A colloid mill rotor is an 2023年12月24日 — crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticCrushing Plant Design and Layout Considerations MINE The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated that mechanical size reduction of rocks, ores, coals, cement, plastics,Size Reduction of Solids Crushing and Grinding EquipmentSemantic Scholar extracted view of "Crushing and grinding : the size reduction of solid materials" by G C Lowrison to achieve optimum combustion for the boilers in a power plant, are made up of power input to carry on an energy intensive comminution Expand 1 Crushing and grinding : the size reduction of solid materials

(PDF) Crushing Plant Dynamics ResearchGate

2015年10月15日 — The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective in minerals 2017年3月4日 — [Show full abstract] of size reduction methods involved in mineral processing using crushing equipments Crushing is the first step of mineral processing where the ore/rocks from the mine site is (PDF) SIZE REDUCTION BY GRINDING METHODS2023年2月28日 — Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications These plants find application in quarrying, mining, construction, and recycling operations Stone crusher plants consist of several components, including a primary crusher, Crushing it: A Comprehensive Guide to Stone Crusher Plants2021年3月1日 — Objectives of size reduction: To aid efficient processing of solid particles by facilitating powder mixing The production of suspensions Exposing cells prior to extraction Reducing the bulk volume of a material to improve transportation efficiency Increase the surface area because, in most reactions involving solid particles, the rate of reactions is Industrial Pharmacy ParticleSize Reduction Dr

.jpg)

Design of a crushing system that improves the crushing

2016年2月10日 — diameter before pure gold can be extracted from them The ore usually has to pass various crushing stages, each reducing the ore to a certain size Crushing plant layout is of vital importance Goldcontaining rocks are crushed for several reasons Crushing reduces the physical size of large rocks, exposing more surface area of rock, 2013年4月1日 — 1 Introduction Crushing plant’s design relay on accurate plant simulations Crushing plants are designed to be able to produce certain throughput on predefined specification (ie a certain particle size distribution) and a certain particle size distribution while operating at a reasonable cost and at efficient energy consumptionModelling and simulation of dynamic crushing plant2021年11月29日 — AusIMM Metallurgical Plant Design and Operating Strategies Conference April 2002 Page 3 – R Longley; N Katsikaros; C Hillman “A New Age Gold Plant Flowsheet for the Treatment of High Grade Ores” Crushing and grinding The first stage of the treatment process is the size reduction of the ore particles down to a sizeA New Age Gold Plant Flowsheet Gekko S2022年4月26日 — The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective in minerals (PDF) Optimization Capabilities for Crushing Plants

.jpg)

Assessing the energy efficiency of a jaw crusher ScienceDirect

2014年9月1日 — Coarse crushing: Kick: 01 As the main goal is to model particle size reduction in compression comminution equipment, a calibration scheme was selected based on single particle breakage using constant velocity moving plates [5] This calibration procedure requires extensive knowledge of the material physical properties for 2015年2月25日 — Size reduction equipment Duty Feed Size Product Size Coarse Up to 1 m3 100150 mm Medium Upto 150 mm 3575mm Light Upto 100 mm 2550mm Fines 25 mm 150 micron Ultra fines 1 mm 74 micron Coarse and medium duty crushers are generally used as Primary Crushers, Medium and light crushers are generally used as secondary Crushing of coal and calculation of size reduction efficiencyreducing the size of coarse line using crushing plant reducing the size of coarse limestone using crushing Quarry fines minimisation NERC Open Research Archive crushing plant also helps to reduce fines production, including: reducing the low size reduction ratio (6:1) and is characterised by the use of certain types of limestone, igneous and metamorphic rock, reducing the size of arse line using crushing plant MC 2023年10月20日 — The HydroFloat is a fluidizedbed coarse particle flotation machine that overcomes the limitations of conventional stirred tank flotation machines to allow for flotation of particles that are two to three times coarser, as shown generally for copper concentrating in Fig 1The HydroFloat achieves these breakthrough results by overcoming buoyancy The Role of Coarse Particle Flotation in the Development of

.jpg)

Mobile crushing and Screening Plant Applications for

2024年9月18日 — The crushing plant, with high flexibility, can be combined into either a twosection screening system of coarse and fine crushing or a threesection screening system of coarse, medium and fine crushing according to the actual requirements The main advantages of mobile, trackmounted primary crushing plants are their2017年3月4日 — The details of size reduction methods involved in mineral processing are using crushing equipments (Balasubramanian, 2017) Ore dressing is a process of mechanically separating the grains of (PDF) SIZE REDUCTION BY CRUSHING a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the aggregates industry is to development for coarse comminution process A case study of Geita gold mine, Tanzania using Plantsmith process simulatorOptimization Capabilities for Crushing Plants Chalmers2017年6月2日 — Rittinger’s Law states that the energy required in size reduction is proportional to the new surface created by the particle fragmentation The equation for Rittinger’s Law can be written as: E = K How it Works: Crushers, Grinding Mills and

911 Metallurgist

2024年9月24日 — %PDF12 %âãÏÓ 114 0 obj /Linearized 1 /O 116 /H [ 1107 524 ] /L /E 29615 /N 29 /T >> endobj xref 114 34 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 2023年12月1日 — 2 All crushers have a limited reduction ratio meaning that size reduction will take place in stages 32 Operation stages: The operating stages in minerals processing have remained the same for SIZE REDUCTION BY CRUSHING METHODS ByCrushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple , the ore is blended and fed to crusher by loader bucket for size reduction Crushing is (PDF) Field monitoring and performance evaluation of crushing plant Crushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing" Although there is no limit set, the downsizing process over 3 mm is considered as "crushing WHAT IS THE CRUSHING PROCESS? MEKA

.jpg)

CRUSHING PLANT PROCESS OPTIMISATION AusIMM

2024年9月18日 — purpose of size reduction and often also classifi cation The confi guration of a crushing stage varies Using dynamic simulation of crushing plants will also need a lot more information then what normally is available at the design phase of the crushing plant construction A steady state simulation of a crushing plant begins with the A research group now known as the Julius Kruttschnitt Mineral Research Centre at the University of Queensland has been working since 1962 on the simulation, optimization and control of mineral treatment processes The initial work was on the grinding and classification processes This work has been very successful in the optimization (Lynch, [PDF] The Simulation of Crushing Plants with Models Developed using 2023年2月28日 — The primary objective of crushing is to reduce the size of the materials for further processing Crushing is an energyintensive process that involves different types of equipment, such as crushers, screens, and conveyors 200t/h Pebble Crushing Mobile Production Line; 150t/h Granite Mobile Crushing Plant; 100t/h Slag Mobile Crushing Plant Primary and Secondary Crushing: Understanding the Basics